What is robotics?

Robotics is the convergence of Science, Technology, and Engineering that manufactures machine commonly known Robots that is a replacement for human activities. As machinery is advancing, the range of Robotics in the industry is also advancing.

In 2005, 90% of the automotive factory that makes cars are found using robots for their workers’ convenience and safety. Car factories use robots mainly for the screwing and wielding on specific parts of the automobiles.

We are currently noticing diverse versions and definitions that comprise expansion, formation, and utilization of robots, also known as automation, Android machine, or Autobots, that investigate Worlds severe circumstances. The Robot helps police forces, and Robot also provides aid in nearly every field of medicine.

As time is passing by, the entire world of robots is enlarging, but whatever the era or machine it is, robots have some prominent features, which are as follows.

1. All robots comprises of some mechanical establishment. This mechanical side of robots assist them to finish their work for which they are designed in the right atmosphere; for example, Robot Mars 2020 Rover’s wheels are independently mechanized, and its tubes are made of Titanium which supports it to have a solid hold on the rough ground of the red planet.

2. Electric-powered elements are essential for a robot to manage and charge the machine. A wide range of robots needs an electric current to charge or give power to the machine.

3. Robots hold at least a certain amount of computer programming and need some instruction or code to insert in them to work; without them, a robot is just kind of an ordinary machine. Feeding a command into the robots allows the control to know at what time and how the command has to be done.

The robots industry is comparatively new from the different mechanical Industries but has already made its name in the field. There is nothing a robot cannot do from the bottom of the ocean too far above in this space. They are capable of doing those things too, which humans will think twice before doing.

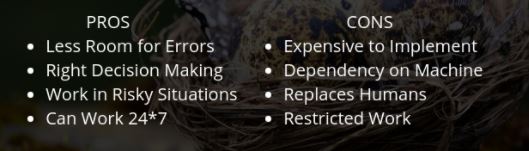

What are the advantages and disadvantages of robotics?

As many automobile companies start to acknowledge the benefits and advantages of robotic automation, it rapidly increases the machine’s popularity ratio.

Essentially not everyone has been satisfied by the advantages robotic automation has to deliver. There are still some reasonable concerns from the buyers or companies who did not try this technology and are hesitant to apply.

Following are the advantages and disadvantages of robotic automation.

Advantages:

* Cost-effectiveness:

The robots can work as long as they are programmed to do so without any break. This causes the rise in construction at a minimum price which is profitable for any manufacturer. The money invested in the company can be paid off in a short span, and then there is only profit onwards.

* Improve quality assurance:

There are few laborers in the company who love to do the same task repeatedly, but after some time, their concentration level decreases, resulting from the high-cost errors and often causes severe injuries to the staff members. Robots automatically decrease these kinds of threats by correctly generating and examining products that meet the given caliber.

*Increase productivity:

Robots are designed to do the repetitive task without making any error even on the other hand can do this job, but a second time this widget in robotic increases the benefits in the manufacturing process.

*Work in a hazardous environment:

Many possible injuries and accidents usually happen in the workplace as workers have to do their job in the dangerous domain. For example, there is a high chance of getting injured in the presence of chemicals, but robotic automation is the perfect solution as it will do the work nonstop without getting harm or injured.

Disadvantages:

*Potential job losses:

If every company starts using robots for their work to be done faster, then the fear is that there will be no need for humans in factories which can affect humans’ lives.

* Initial investment cost:

This is commonly the most significant hurdle on which robotic automation investment is based on whether or not the company should invest in buying the robots or wait for the more prominent and Greater opportunity.

* Hiring skilled staff:

It is hard for the manufacturers to find the skilled and efficient staff to take the factories’ position and control the robots; they need highly qualified officials who understand their functions correctly. Nevertheless, if we see the upside of this problem, it allows employees to work hard, train and expand their skill set.

Hope the readers would have more clarity after reading this piece. Any comments or suggestions are welcome as we strive to make technology easier for everyone.